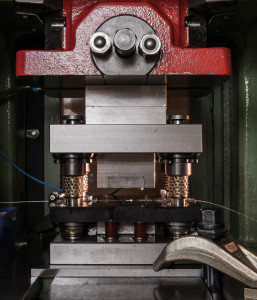

Stamping Technique

Quality and efficiency at world class level

Equipped with KAISER-automatic punching presses and HYDRAP-hydraulic presses we are able to craft stamped parts with a tape thickness of 0.05 to 2.0mm and a tape width up to 120mm from all established materials and surfaces dependably and with high flexibility. We implemented flexible processing with short control circuits due to our long-time experience in process optimization – also in our own factory. So we’re not only able to lower costs and save time, but as well to adapt to the variable needs of our purchasers.

Precision-stamped parts: Highest demands on surfaces and edge geometry – from the first sample to serial production. The whole production process is controlled centrally and planned with utmost precision – from material supply to packaging to transport. So we succeeded ever to stand up to East Asian competitors through quality and reliability. High-technology measuring and testing instruments ensure in conjunction with our highly qualified employees the quality of our products and services. Of course we fulfill the ISO 9001, ISO/TS 16949 and ISO 12485 standards.

We produce most demanding precision-stamped parts:

- for the compressor industry

- for the jewelry industry

- for the electric and electronic industry

- as well as for the automotive sector

Short throughput times via intelligent tool concepts – this enables us to get rapidly from the prototype to steady serial production and offer you our stamping services at low-cost and promt conditions in small and big quantities.