STAMPING TECHNIQUE: Embossing process development

and introduction.

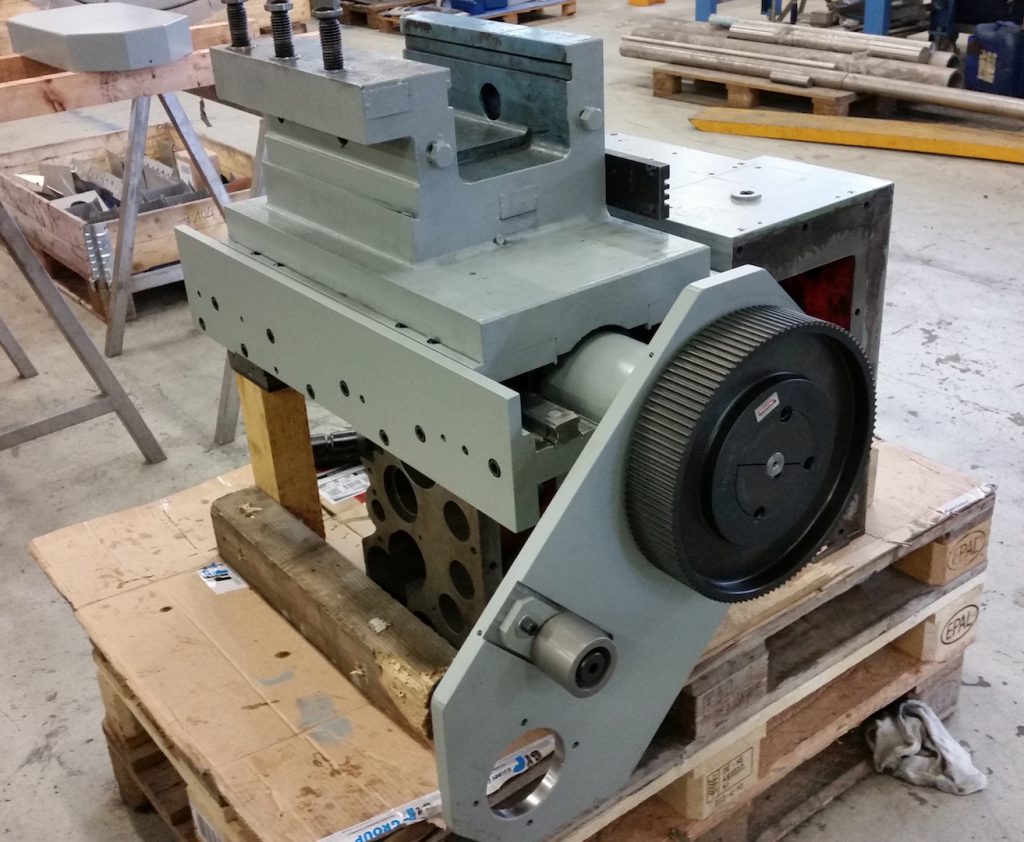

- Developing and implementation of the embossing process in consideration of capacity and process capability

REALIZATION:

- First stamping tests within our tool construction (Criteria: Form of the monogram, contrast between the polished surfaces and the monogram)

- Producing the original form of the embossing stamp

- Tests about the necessary roughness of the embossing stamp

- Digitalizing the located forms and surfaces

- Producing the standard molds

- Establishing the FMEA and installing the inspection plan